OMRON

OMRON

Servomotors / Servo Drivers

Servomotors and Servo Drivers are provided for the purpose of high-speed, high-precision control. The G5 series has a direct connection to the NJ controller via EtherCAT. Customers can design faster, more advanced machine automation control systems. OMRON offers different products in different areas. So please click on the banner "Products links" in the top right corner to reach the country website nearest you.

Servomotors / Servo Drivers List

There are 3 products of Servomotors / Servo Drivers.

G5 Series AC Servomotor/Servo Drives with built-in EtherCAT Communications.

R88M-K, R88D-KN[]-ECT

The G5 series has a direct connection to the NJ controller via EtherCAT. Customers can design faster, more advanced machine automation control systems.

G5-series AC Servomotors/Servo Drives with Built-in MECHATROLINK-II Communications

R88M-K, R88D-KN[]-ML2

MECHATROLINK-II network communication modules are now available for the G5 series.

G5-series AC Servomotors/Servo Drives with General-purpose Pulse Train or Analog Inputs

R88M-K, R88D-KT

Pulse and analog input modules are now available for the G5 series.

Support for a Wide Range of Applications with Position Control, Speed Control and Torque Control.

Note:

OMNUC G Series is the recommended substitute model for U Series (R88M-U/R88D-U). Contact us for more details.

G Series Solutions :

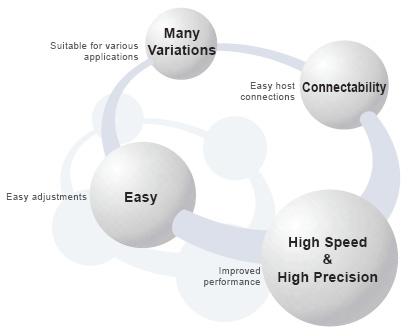

Let the G Series solve your equipment problems!

Increase Productivity!

The many variations provided by G-series Servo Motors and Servo Drivers features high-precision positioning with improved response and vibration control, making it suitable for a variety of applications.

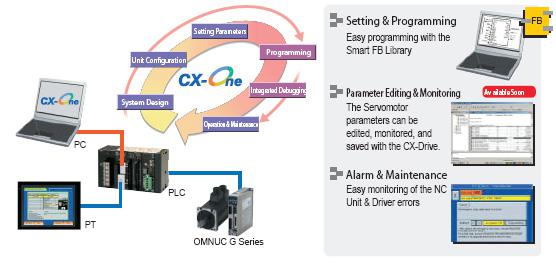

Integrated Development Environment Cut Your TCO from Design to Maintenance

MECHATROLINK-II-compatible AC Servo Motors / Servo Drivers

One Cable Enables Setting and Monitoring Parameters

Connect the PLC and Servo Driver with a single cable to reduce wiring. What's more, the parameters for many Servo Drivers can be set and monitored at the same time between a personal computer and the Controller.

CX-One

Easily Program Positioning and Communications

With the CX-One FA Integrated Tool Package, parameters settings, program design, debugging, operation monitoring, alarms, error monitoring, and maintenance of the Servo System can be handled with ease.

Easy!

Easy Adjustment

Realtime autotuning sets the optimum gain.

An autotuning function calculates the device load in realtime and automatically sets the optimum gain, simplifying the adjustment procedure.

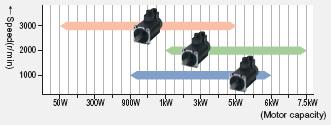

Select the Optimum Motor

A wide range of Servo Motors is available to meet application needs.

You can select a suitable Servo Motor from a wide range of Servo Motor capacities to cater to various applications.

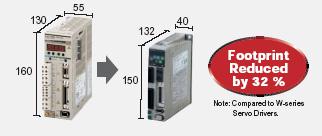

Reduce Control Panel Installation Space

Even smaller Servo Drivers.

The footprint of the Servo Drivers has been reduced by 32% compared to previous OMRON models (see note), helping to reduce control panel size.

Advanced Performance!

Reduce Tact Time

Significantly better speed response frequency.

The speed response frequency has been improved by a factor of 2.5 compared to previous OMRON models. (See note.) The stabilization time has been reduced, increasing machine speed and response performance.

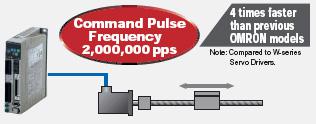

Reduce Tact Time

Fast positioning with improved command pulse frequency performance.

The command pulse frequency is 4 times faster than previous OMRON models. (See note.) This enables fast, accurate control.

Improve Processing Accuracy

All Servo Motors contain a 17-bit encoder*1 for greater accuracy.

Positioning is twice as accurate as previous OMRON models*2 for submicron accuracy. This enables stable control in the low speed range.

- For Servo Motors with absolute encoders.

- Compared to W-series Servo Motors. (Servo motors with absolute encoders, 750 W max.)

Advanced Functionality!

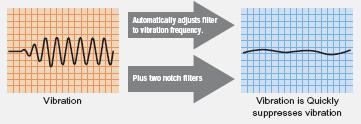

Reduce Mechanical Vibration

Quick suppression of vibration with an adaptive filter.

Even if the resonant frequency changes, realtime evaluation automatically follows the changes to reduce the effect of vibration due to low mechanical rigidity, such as for conveyer belts.

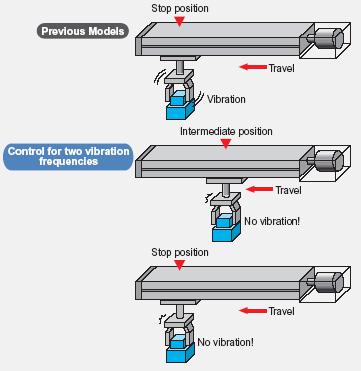

Reduce Tact Time

Reduce mechanical vibration with the vibration control function.

By removing the vibration frequency components between the stop position and the intermediate position, vibration that occurs due to low mechanical rigidity can be suppressed.

Flexible Application

Change the command control mode as required by the application.

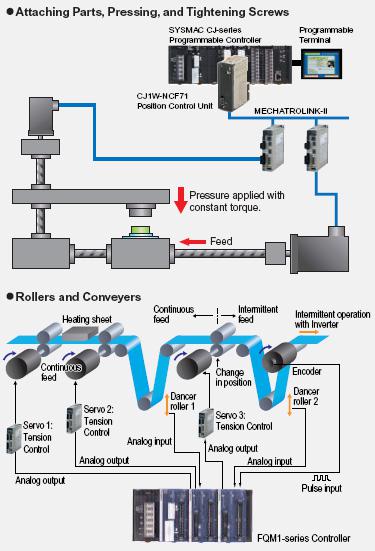

Select from position control, speed control, and torque control for use in applications such as the pressing, tension, and injection.

Other Features

High-speed Response

The G-series AC Servo Motors and Servo Drivers have achieved high-speed response capabilities exceeding OMRON’s W-series models, with a high-response frequency of 1 kHz (compared to 400 Hz for the W Series).

Suppressing Vibration of Low-rigidity Mechanisms during Acceleration / Deceleration

The damping control function suppresses vibration of low-rigidity mechanisms or devices whose ends tend to vibrate. Two damping filters are provided to enable switching the vibration frequency automatically according to the direction of rotation and also via an external signal. In addition, the settings can be made easily merely by setting the vibration frequency and filter values, and you are assured of stable operation even if the settings are inappropriate.

High-speed Positioning via Resonance Suppression Control

The real-time auto-tuning function automatically estimates the load inertia of the machine in real-time and sets the optimal gain. The adaptive filter automatically suppresses vibration caused by resonance. Also, two independent notch filters make it possible to reduce vibration of a mechanism with multiple resonance frequencies.